- VISIT NEW WEBSITE - www.randallfoils.com -

Fitting Guide

Temporary fitting

UPDATE: X-TACK TEC 7 Adhesive has now been fully tested and is available for sale here.

UPDATE: X-TACK TEC 7 Adhesive has now been fully tested and is available for sale here.

The foils are shaped to fit a variety of blades and will bend to conform to your oar. The curve is exaggerated to ensure a secure and tight hold as the joint is under extreme pressure during the stroke.

The angle of the foil will be set according to the profile of your blade - it is not set at 90-degrees.

This video shows a Concept 2 Fat Sweep Blade correctly set (prior to final clean-up).

There are many adhesive options which will depend on your circumstances.

Check instructions on the adhesive you select.

Materials required

- Randall foil sets

- Heat Gun

- Sharp Pencil

- Sandpaper

- Stanley knife

- Adhesive

- Duct Tape (for bracing and clamping)

- Masking Tape (for masking outside the attachment area)

Preparation

- Use sandpaper to remove any paint or glossy surface. The adhesive needs a light surface texture for it to bite.

- Pencil mark the attachment area - WITHOUT adhesive, place the Randall foil’s on the oars, line up with the outside edge of the blade. Draw around the Randall foil’s - Mark the end with an extra line to indicate where the small end lines up.

- Place masking tape around the outside edge of the pencil line for easy clean-up as the adhesive is very strong!

- Pre-cut 5 pieces of duct tape about 20cm in length. Have them within reach.

- Heat foils with a Hair Drier to assist fitting – Especially C2 Blades

- Fill the Randall foil slot and back surface with the adhesive. Ensure there is more adhesive than required, as the adhesive needs to fill all of the notches and groves.

- Attach the SMALLER end first - brace with duct tape firmly down the BACK edge. As The adhesive will start filling the cavity and any excess will ooze out. Work from the smaller to the wider end of the Randall foil.

- Proceed along until the entire foil is firmly set down. The shape is designed for a tight fit and may be like fitting a bicycle tyre. Don't be afraid to apply pressure to the foil as it will conform to the shape of the blade.

To accommodate a VORTEX STRIP position as per this image

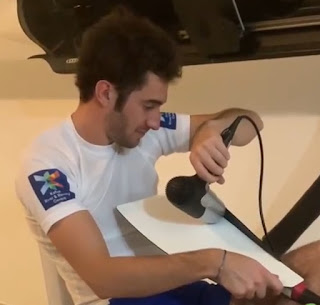

Using clamps for C2 'Fats' when permanently fitting with 2-part fiberglass resin or professional grade adhesive.

Additional Strengthening - drill 3mm holes through from the joining slot. The resin will fill the cavity creating a strengthening bolt.

Getting Serious - Using Real Screws (see below)

- Ensure full curing of adhesive.

- Carefully remove all tape.

- Use a Stanley knife cut away any excess adhesive.

Rigging and Pitching Guide

- Raise your gates at least 2 washers (6mm) as you won't be burying your blade as deeply. This is important as you want to keep your hand heights the same as you are practised. Without this change, you will be fighting against the design of the foil and be forcing the blade down below the surface.

- Set blade pitch at or close to Zero-degrees pins set at Zero-degrees - IMPORTANT : Zero- degrees pitch is optimal for foil performance. Without this change, you will experience a sensation of wash or water turbulence during the stroke.

- You will need gate inserts to alter blade pitch: No.7 = 1-degrees / No.6 = 2-degrees / No.5=3-degrees.

- Top insert faces away from the gate

- Bottom insert faces toward the gate

RANDALLfoil is protected under international intellectual property rights